Deep Drawing Operation

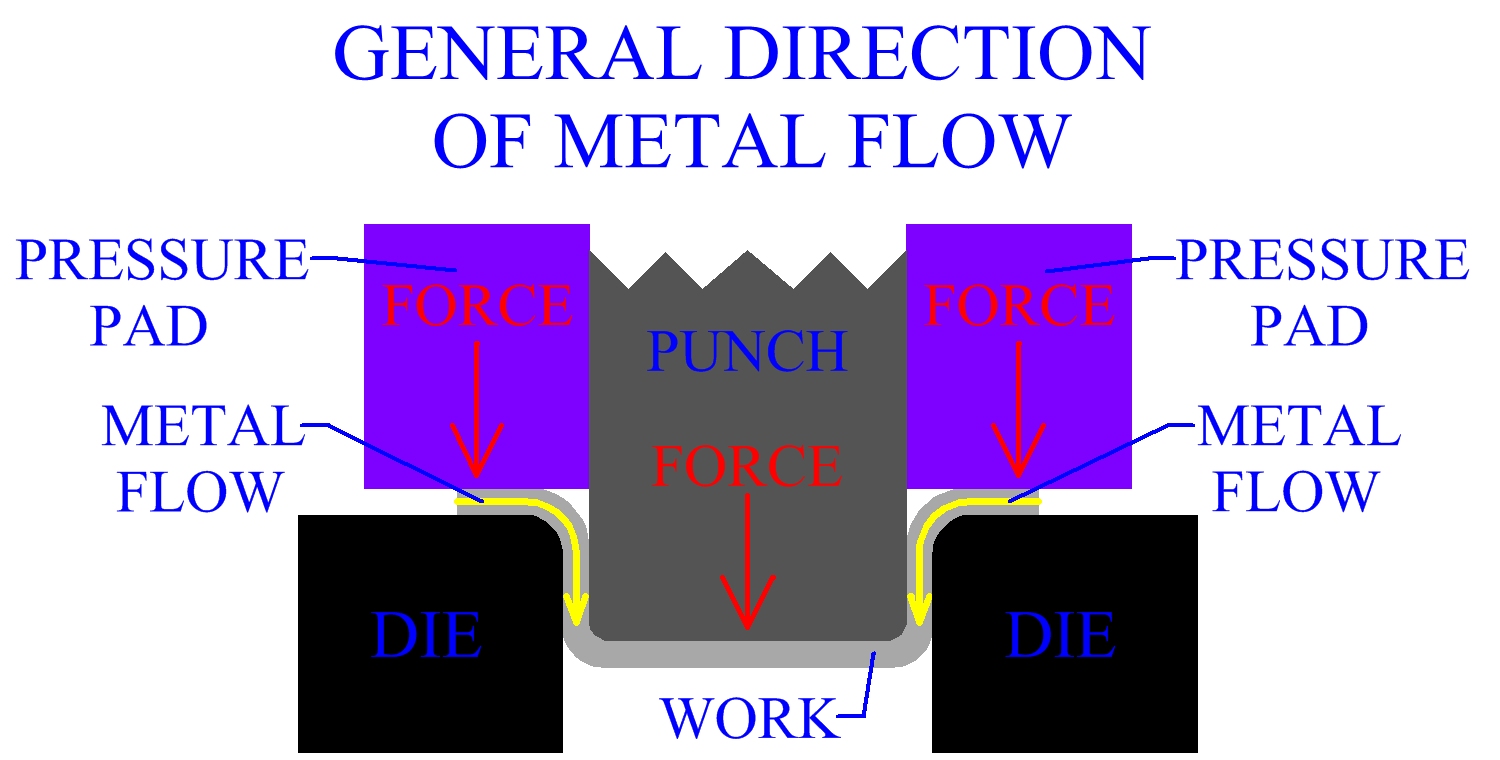

Deep Drawing Operation - 1.1 what are the key factors affecting sheet metal drawing? Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. 2.1 the deep drawing process. 1 what is sheet metal drawing? This operation involves placing a metal blank above a mold cavity and holding it with a blank holder. Its versatility and efficiency have made it an indispensable tool in various industries. Deep drawing load and its components and their variations with punch movement. Web the deep drawing operation is not just about shaping metal; Too little force, and the process will stall. The process involves a punch with a round comer and a die with a large radius. Web this article highlights only the most frequently violated design and build principles. It is thus a shape transformation process with material retention. Similar to stamping operation, deep drawing utilizes single piece blanks. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention. Although designing and building deep draw dies is fast becoming a science, the fundamental metal flow principles should never be ignored, for they are the foundations of a successful deep drawing operation. 1 what is sheet metal drawing? The metal thickness, the metal type, and the blank size. 2.2 factors influencing the deep drawing process. Its versatility and efficiency have made it an indispensable tool in various industries. It uses lines and points to give a sense of distance in views of the outdoors, interiors and imaginary spaces. Its versatility and efficiency have made it an indispensable tool in various industries. Web for a successful deep draw, enough force must be applied to the punch to deform the blank, initiate metal flow, and overcome friction. Web deep drawing, a cornerstone of modern manufacturing, is a metal forming process that’s used to shape flat sheets of metal into seamless, hollow components. 1.1 what are the key factors affecting sheet metal drawing? Web deep drawing is a sheet metal forming process in which a flat blank is constrained by a blank holder while the central portion of the sheet is pushed into a die opening with a punch to draw the metal into the desired shape without causing wrinkles or splits in the drawn part (demeri, 2006). Web table of contents hide. In this guide, we’ll discover the detailed steps involved in deep drawing, from material selection to the final inspection. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. The process is considered deep drawing when the depth of the drawn part exceeds its diameter. Web for a successful deep draw, enough force must be applied to the punch to deform the blank, initiate metal flow, and overcome friction. Web deep drawing is utilized to transform flat sheet metal into deep, hollow shapes by mechanically pulling the material into a forming die, creating parts with considerable depth relative to their diameter, such as. 3 applications. 2.2 factors influencing the deep drawing process. It is thus a shape transformation process with material retention. It is thus a shape transformation process with material retention. The process involves a punch with a round comer and a die with a large radius. The metal thickness, the metal type, and the blank size. Although designing and building deep draw dies is fast becoming a science, the fundamental metal flow principles should never be ignored, for they are the foundations of a successful deep drawing operation. Properties of work metal for optimal formability. Deep drawing load and its components and their variations with punch movement. Similar to stamping operation, deep drawing utilizes single piece. It produces components with deeper shapes. Web deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. It is thus a shape transformation process with material retention. 2.2 factors influencing the deep drawing process. Web deep drawing is one of the most widely. Web introduction to deep drawing. Web deep drawing is one of the most widely used processes in sheet metal forming, in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Web deep drawing is a forming procedure in which sheet metals are pressed into a die cavity and establish into. Derivation of mathematical expression for load and its comparison with sachs relation. Web deep drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of tensile and compressive forces. Web this article highlights only the most frequently violated design and build principles. It is thus a shape transformation process with. 3 applications and industries benefiting from deep drawing. It produces components with deeper shapes. The process involves a punch with a round comer and a die with a large radius. Web deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. Web deep. 2.2 factors influencing the deep drawing process. The process involves a punch with a round comer and a die with a large radius. 2 deep drawing sheet metal : 2.1 the deep drawing process. It produces components with deeper shapes. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It produces components with deeper shapes. Web deep drawing is a forming procedure in which sheet metals are pressed into a die cavity and establish into a desired shape. Web this. Its versatility and efficiency have made it an indispensable tool in various industries. Understanding the basics of deep drawing. Deep drawing load and its components and their variations with punch movement. Web table of contents hide. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the. Web doug mills/the new york times. Deep drawn parts achieve their shape by drawing metal into a cavity rather than by stretching or thinning over a die, so the original sheet thickness remains essentially the same from start to. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Similar to stamping operation, deep drawing utilizes single piece blanks. 1 what is sheet metal drawing? Deep drawing load and its components and their variations with punch movement. Web deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. It produces components with deeper shapes. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Web this article highlights only the most frequently violated design and build principles. A blank holder is used to prevent wrinkling in the product, especially with thin sheets. 2 deep drawing sheet metal : Web for a successful deep draw, enough force must be applied to the punch to deform the blank, initiate metal flow, and overcome friction. Web deep drawing is a sheet metal forming operation where sheet metal blank is drawn into hollow shapes by utilizing the combination of tensile and compressive forces. Web the important variables involved in the deep drawing operation includes friction, squeezing force and formability of the metal blank. Web table of contents hide.Deep Drawing

Deep drawing of sheet metal

Stamping Die Essentials Deep drawing Dynamic Die Supply

What Is Deep Drawing ? Working Of Deep Drawing Sheet Metal Processes

Deep Drawing Of Sheet Metal

Deep Drawing Process for Sheet Metal IspatGuru

What is Deep Drawing Process? Mech4study

03_04_P1 Important Process Parameters in Sheet Metal Drawing or Deep

Deep Drawing Of Sheet Metal

Deep Drawing Of Sheet Metal

Web The Manufacturing Of Deep, Cuplike Products From Thin Sheet Metal Is Known As Deep Drawing.

Pots And Pans For Cooking, Containers, Sinks, Automobile Parts, Such As Panels And Gas Tanks, Are Among A Few Of The Items Manufactured By Sheet Metal Deep Drawing.

Web Introduction To Deep Drawing.

1.1 What Are The Key Factors Affecting Sheet Metal Drawing?

Related Post: