Dimensioning In Engineering Drawing

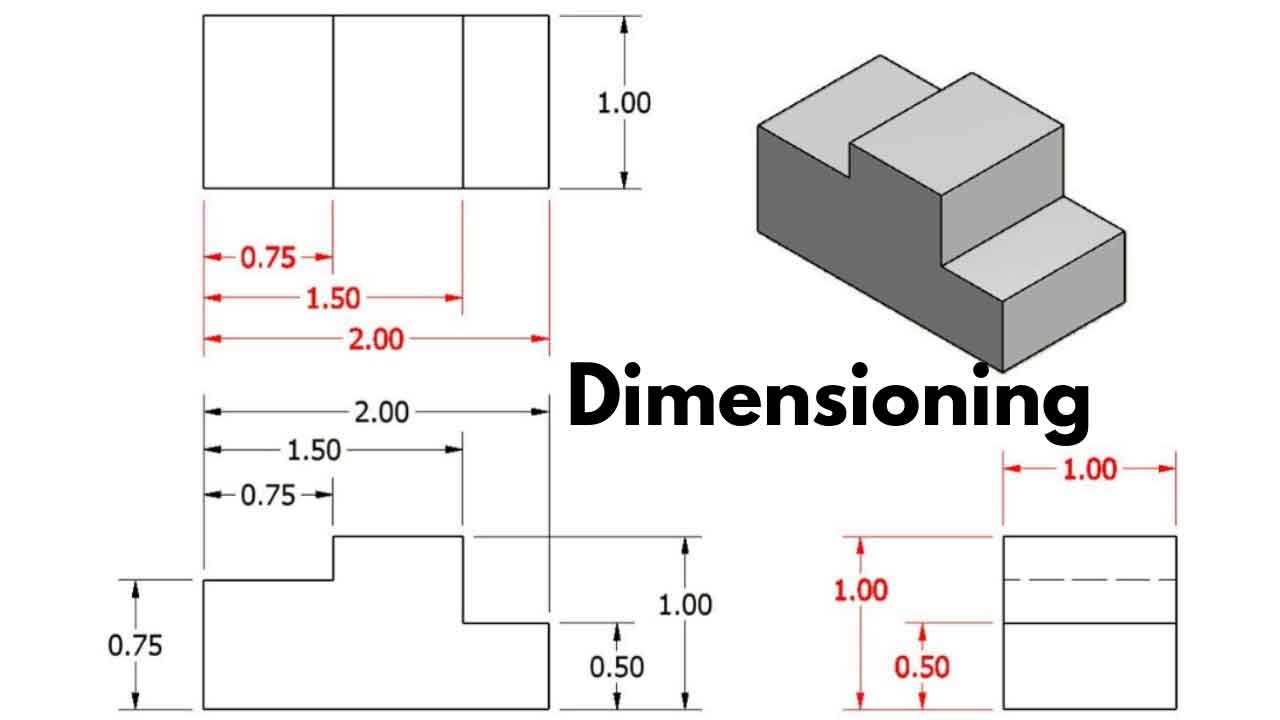

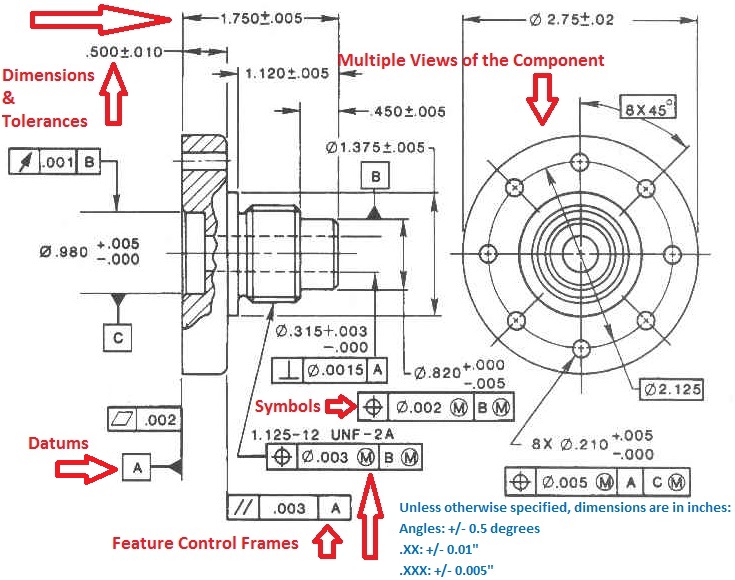

Dimensioning In Engineering Drawing - For example, the distance between different surfaces, the location of holes, number of holes, type of material, etc. Once the shape of a part is defined with an orthographic drawings, the size information is added also in the form of dimensions. Web on a multiview drawing, dimensions should generally be placed between adjacent views. Sometimes, you will have to place dimensions in two units simultaneously! Web essentially, dimensioning refers to the process of specifying the exact size, shape, and location of different parts and features on an engineering drawing. Web the process of adding size information to a drawing is known as dimensioning the drawing. Using gd&t results in a more accurate design, larger tolerances for less important design features, and cost savings for manufacturing. Usually, a number of drawings are necessary to completely specify even a simple component. Web deep drawing is the process of drawing sheet metal blank into a desired shape. Web in this video, we are going to learn about dimensions in engineering drawing! Web the process of adding size information to a drawing is known as dimensioning the drawing. Dimensions should be placed strategically to avoid crossing extension lines, unless doing so would clutter the drawing or move the dimension too. Avoid dimensioning to a hidden line and avoid the duplication of dimensions. Web on a multiview drawing, dimensions should generally be placed between adjacent views. Web the common metric unit of measure on engineering drawings is the millimeter, abbreviated as mm. Correct values must be given. Web deep drawing is the process of drawing sheet metal blank into a desired shape. Learning and understanding of how dimensions are mentioned are very easy if you focus on learning. Web dimension lines are used to indicate the size and location of features in an engineering drawing. We are going to look at what dimensioning is, what are the elements of the dimensions and what the rules for. Web as we previously mentioned, we use dimensions to define the size and shape of an engineering component. Web sometimes, however, it is necessary to dimension on the object. Web essentially, dimensioning refers to the process of specifying the exact size, shape, and location of different parts and features on an engineering drawing. They provide measurements that define the length, width, height, or diameter of objects, allowing for accurate replication and manufacturing. Dimensions in engineering drawings are numerical values indicated graphically in a proper unit of measurement on engineering drawing with lines, symbols, and notes. Dimensions must be placed in appropriate positions. Web engineering drawings and sketches need to display simplicity and uniformity, and they must be executed with speed. Web learn everything you need to know about dimensioning engineering drawings. Web the process of adding size information to a drawing is known as dimensioning the drawing. Web in this video, we are going to learn about dimensions in engineering drawing! Rule 1) dimensions should be arranged for maximum readability. Our comprehensive guide covers techniques, standards, and best practices for accuracy and clarity. Web the process of adding size information to a drawing is known as dimensioning the drawing. Web geometric dimensioning and tolerancing (gd&t) is a system of symbols and standards used in engineering drawings and models to specify the. Web deep drawing is the process of drawing sheet metal blank into a desired shape. Web dimension lines are used to indicate the size and location of features in an engineering drawing. Web engineering drawings and sketches need to display simplicity and uniformity, and they must be executed with speed. Geometrics is the science of specifying and tolerancing the shapes. Web in this video, we are going to learn about dimensions in engineering drawing! Web gd&t, short for geometric dimensioning and tolerancing, is a system for defining and communicating design intent and engineering tolerances that helps engineers and manufacturers optimally control variations in manufacturing processes. Geometrics is the science of specifying and tolerancing the shapes and locations of features on. A common use is to specify the geometry necessary for the construction of a component and is called a detail drawing. Web essentially, dimensioning refers to the process of specifying the exact size, shape, and location of different parts and features on an engineering drawing. Web geometric dimensioning and tolerancing (gd&t) is a system of symbols and standards used in. Web sometimes, however, it is necessary to dimension on the object. In other words, with the use of dimensioning technics on the engineering drawings, we define the physical boundaries of the component, like the size and location of the different features. Usually, a number of drawings are necessary to completely specify even a simple component. Web the common metric unit. Correct values must be given. Web geometric dimensioning and tolerancing is used to communicate detailed information on technical drawings. Web what is dimensioning in engineering drawing? It is important to remember to place dimensions on the views, in a two or three view drawing, where they will be the most easily understood. Geometrics is the science of specifying and tolerancing. Dimensions must be placed in appropriate positions. Web essentially, dimensioning refers to the process of specifying the exact size, shape, and location of different parts and features on an engineering drawing. In other words, with the use of dimensioning technics on the engineering drawings, we define the physical boundaries of the component, like the size and location of the different. Web sometimes, however, it is necessary to dimension on the object. A blank holder is used to prevent wrinkling in the product, especially with thin sheets. Avoid dimensioning to a hidden line and avoid the duplication of dimensions. It is important to remember to place dimensions on the views, in a two or three view drawing, where they will be. Standardization of gd&t and knowledge of those standards is crucial to ensure that the design intent is communicated properly. A dimension is a numerical value that expresses the size, location, orientation, form, or any other geometric properties of a component in the appropriate units of measurement. Web essentially, dimensioning refers to the process of specifying the exact size, shape, and. For example, the distance between different surfaces, the location of holes, number of holes, type of material, etc. Web learn everything you need to know about dimensioning engineering drawings. Web geometric dimensioning and tolerancing (gd&t) is a system of symbols and standards used in engineering drawings and models to specify the required form, size, orientation, and location of parts and. A blank holder is used to prevent wrinkling in the product, especially with thin sheets. Correct values must be given. The spacing between dimension lines should be uniform throughout the drawing. Dimensions must be placed in appropriate positions. In other words, with the use of dimensioning technics on the engineering drawings, we define the physical boundaries of the component, like the size and location of the different features. Dimensioning is vital in the engineering industry as it ensures that the final product meets the required standards and specifications. Standardization of gd&t and knowledge of those standards is crucial to ensure that the design intent is communicated properly. Web an engineering drawing is a type of technical drawing that is used to convey information about an object. Dimensions should be placed strategically to avoid crossing extension lines, unless doing so would clutter the drawing or move the dimension too. Sometimes, you will have to place dimensions in two units simultaneously! Rule 1) dimensions should be arranged for maximum readability. Dimensions in engineering drawings are numerical values indicated graphically in a proper unit of measurement on engineering drawing with lines, symbols, and notes. Engineering drawing has evolved into a language that uses an extensive set of conventions to convey information very precisely, with very little ambiguity. Web geometric dimensioning and tolerancing (gd&t) is a system of symbols and standards used in engineering drawings and models to specify the required form, size, orientation, and location of parts and features. For example, the distance between different surfaces, the location of holes, number of holes, type of material, etc. Web deep drawing is the process of drawing sheet metal blank into a desired shape.METHOD OF DIMENSIONING ALIGNED METHOD II Engineering drawing II YouTube

Dimensioning and its role in drafting and design

SOLUTION Dimensioning in engineering drawing Studypool

Example of an industrial drawing with dimensioning and tolerancing

Types Of Dimensions In Engineering Drawing at GetDrawings Free download

Types Of Dimensions In Engineering Drawing at GetDrawings Free download

Dimensioning Drafting Drawings

Types Of Dimensions In Engineering Drawing at GetDrawings Free download

GENERAL RULES OF DIMENSIONING in Engineering Drawing YouTube

Technical Drawing Dimensions Design Talk

Web The Process Of Adding Size Information To A Drawing Is Known As Dimensioning The Drawing.

Web Essentially, Dimensioning Refers To The Process Of Specifying The Exact Size, Shape, And Location Of Different Parts And Features On An Engineering Drawing.

A Common Use Is To Specify The Geometry Necessary For The Construction Of A Component And Is Called A Detail Drawing.

Web On A Multiview Drawing, Dimensions Should Generally Be Placed Between Adjacent Views.

Related Post: