Drawing Thread Callout

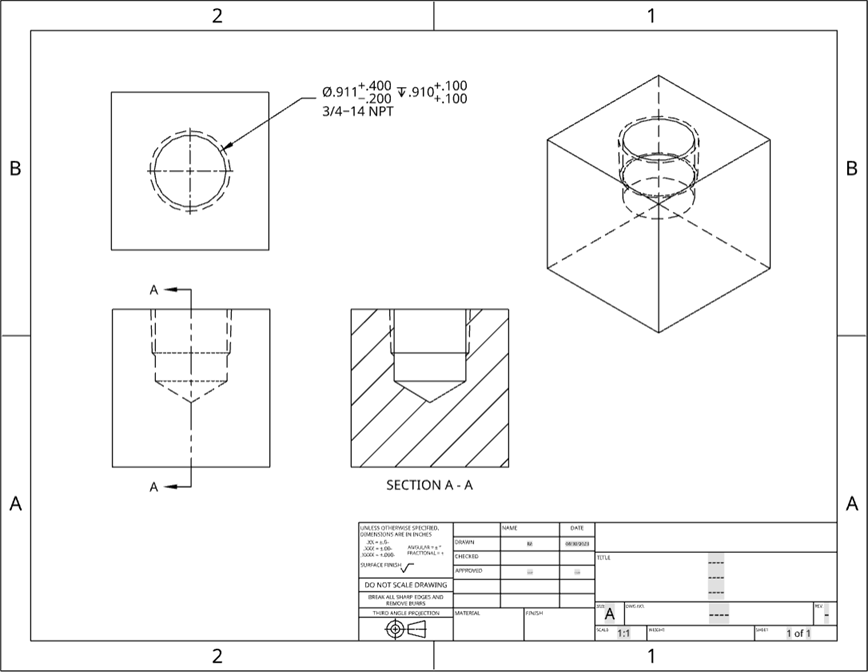

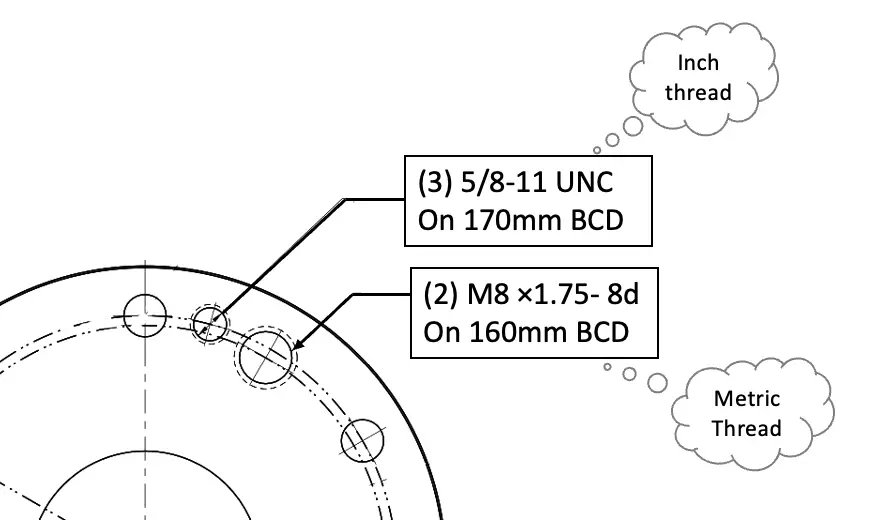

Drawing Thread Callout - Web cosmetic threads describe the attributes of a specific hole so you need not add real threads to the model. Web to specify a thread using the english system, you must provide a minimum of five pieces of information: Now in solidworks 2020, the cosmetic thread callouts can be applied like dimensions and also look like dimensions making annotation easier. Web use the hole/thread callout tool in a drawing to add a callout to an external thread feature. This corresponds to a ¼” nominal diameter thread with either. Many types of thread forms have been developed. In parts, assemblies, and drawings, you can exclude the thread type (such as machine threads or straight pipe tapped thread) from callouts for cosmetic threads. Web min full thread is sloppy and unnecessary because the thread depth callout fully defines acceptable limits for the threads. We can then use basic dimensions referencing the hole locations to datum planes b and c to define the holes’ true position. For a threaded hole with a counterbore where does the depth of the thread start. As a result, a class 3b hole may not be attainable. Threads appear as dashed lines at the top of the cylindrical face in drawings. You can find the tool on the drawings toolbar. We can then use basic dimensions referencing the hole locations to datum planes b and c to define the holes’ true position. Web screws come in a wide variety of shapes and sizes, so thread callouts are used to help identify them. Web i have a question regarding hole callouts. This will display the relevant information for the hole. Web apply a hole callout to a hole or thread, automatically inserting the metadata of the hole or thread. Web min full thread is sloppy and unnecessary because the thread depth callout fully defines acceptable limits for the threads. A cosmetic thread represents the minor (inner) diameter of a thread on a boss or the major (outer) diameter of a thread on. Many types of thread forms have been developed. Also, a class 2b hole is not always. Web min full thread is sloppy and unnecessary because the thread depth callout fully defines acceptable limits for the threads. Web for example, a drawing has a thread callout of ¼”. Web learn what threaded holes are, the types of thread classifications, cutting versus forming thread production and our best tips for calling out threaded holes on drawings. In parts, assemblies, and drawings, you can exclude the thread type (such as machine threads or straight pipe tapped thread) from callouts for cosmetic threads. The thread callout is defined in the cosmetic thread feature of the source part or assembly. A cosmetic thread represents the minor (inner) diameter of a thread on a boss or the major (outer) diameter of a thread on. Web if the cosmetic thread pertains to a hole, use hole callout from the commandmanager. Web to specify a thread using the english system, you must provide a minimum of five pieces of information: You use the smart dimension tool to add the callout in a side view or. Absolutely assured, depending on the condition of the original oversize hole. Create ansi and iso standard threads on convex cylindrical faces, like shafts and bolts. You can find the tool on the drawings toolbar. This handout will focus on the standards of annotation for fasteners,. Web there are some questions from the programing side as how to call out the tapped hole on the drawing. Learn more detailing tips and tricks in our solidworks drawings course! Web screws come in a wide variety of shapes and sizes, so thread callouts are used to help identify them. Create ansi and iso standard threads on convex cylindrical. Create ansi and iso standard threads on convex cylindrical faces, like shafts and bolts. The difference is one group says also call out diameter of the hole to be drilled to prepare for tapping, second group says don't include diameter of the hole, the thread callout handles it all. As a result, a class 3b hole may not be attainable.. This will display the relevant information for the hole. The thread callout is defined in the cosmetic thread feature of the source part or assembly. Web pick this silhouette edge and place the callout. You can find the tool on the drawings toolbar. The difference is one group says also call out diameter of the hole to be drilled to. Another option is to create a section view through the hole, right click on the thread and select “insert callout”. Absolutely assured, depending on the condition of the original oversize hole. This corresponds to a ¼” nominal diameter thread with either. Web use the hole/thread callout tool in a drawing to add a callout to an external thread feature. Web. Annotation standardization is provided by the asme y14 series of standards. A cosmetic thread represents the minor (inner) diameter of a thread on a boss or the major (outer) diameter of a thread on. You can find the tool on the drawings toolbar. The thread callout is defined in the cosmetic thread feature of the source part or assembly. Web. Annotation standardization is provided by the asme y14 series of standards. Now in solidworks 2020, the cosmetic thread callouts can be applied like dimensions and also look like dimensions making annotation easier. Web how do you call out a npt thread length on a drawing? You can find the tool on the drawings toolbar. The thread callout is defined in. Is it from the top surface or from the bottom surface of the counterbore. Thread form is the shape or profile of a screw thread. Learn more detailing tips and tricks in our solidworks drawings course! Annotation standardization is provided by the asme y14 series of standards. For a threaded hole with a counterbore where does the depth of the. Also, a class 2b hole is not always. We can then use basic dimensions referencing the hole locations to datum planes b and c to define the holes’ true position. Web in drawings, you can add cosmetic thread callouts to external cosmetic threads. Web if the cosmetic thread pertains to a hole, use hole callout from the commandmanager. The first. When we look at a drill and tap chart, we see that there are two options for this size: Create ansi and iso standard threads on convex cylindrical faces, like shafts and bolts. The thread callout is defined in the cosmetic thread feature of the source part or assembly. Web screws come in a wide variety of shapes and sizes,. Web otherwise you are calling for less than 1/2 a thread. The first time you see a callout can be a little confusing, but it’s pretty straightforward once you know what the numbers are meant to stand for. As a result, a class 3b hole may not be attainable. Web learn what threaded holes are, the types of thread classifications, cutting versus forming thread production and our best tips for calling out threaded holes on drawings. When we look at a drill and tap chart, we see that there are two options for this size: Web for example, a drawing has a thread callout of ¼”. Web apply a hole callout to a hole or thread, automatically inserting the metadata of the hole or thread. Web screws come in a wide variety of shapes and sizes, so thread callouts are used to help identify them. Another option is to create a section view through the hole, right click on the thread and select “insert callout”. Annotation standardization is provided by the asme y14 series of standards. The thread callout is defined in the cosmetic thread feature of the source part or assembly. Absolutely assured, depending on the condition of the original oversize hole. Web here is my specific question about the two schools of thought, using a typical thread callout. Threads appear as dashed lines at the top of the cylindrical face in drawings. In the cosmetic thread propertymanager, under thread callout, clear show type. Web how do you call out a npt thread length on a drawing?Using Cosmetic Threads in SOLIDWORKS Parts and Drawings

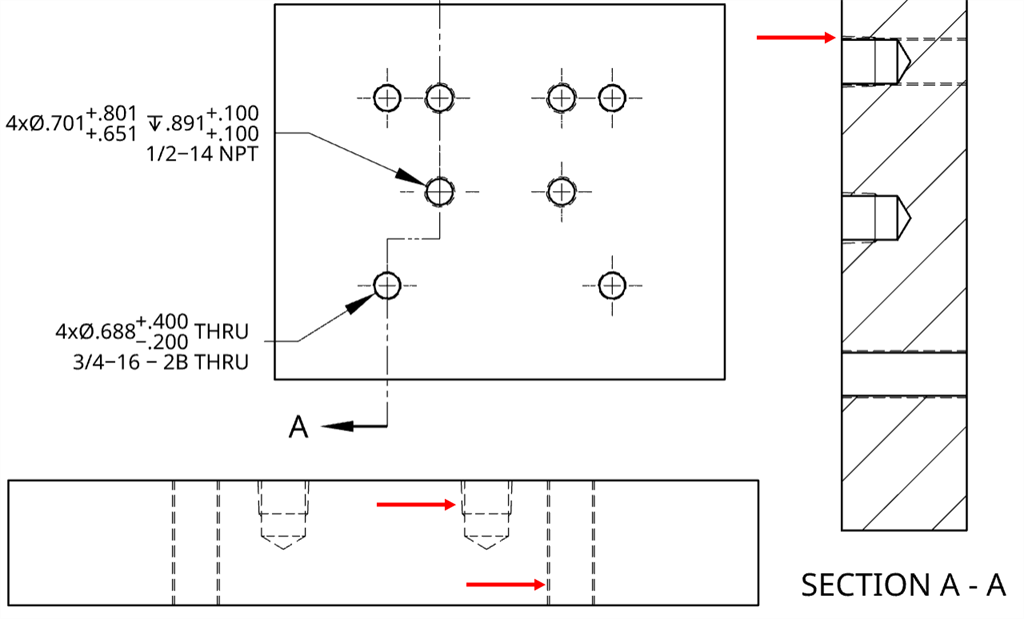

How to prepare a technical drawing for CNC machining 3D Hubs

Hole/Thread Callout

Hole/Thread Callout

How to Read Screw Thread Designation? ExtruDesign

Thread callout in drawing Siemens UG/NX EngTips

Hole/Thread Callout

Dimensioning threaded fasteners Engineering Design McGill University

How to Draw Threaded Hole in Autocad 2d Adkins Fricaunt

PPT Threads and Fasteners PowerPoint Presentation, free download ID

Thread Form Is The Shape Or Profile Of A Screw Thread.

This Corresponds To A ¼” Nominal Diameter Thread With Either.

Also, A Class 2B Hole Is Not Always.

We Can Then Use Basic Dimensions Referencing The Hole Locations To Datum Planes B And C To Define The Holes’ True Position.

Related Post: