Process Of Deep Drawing

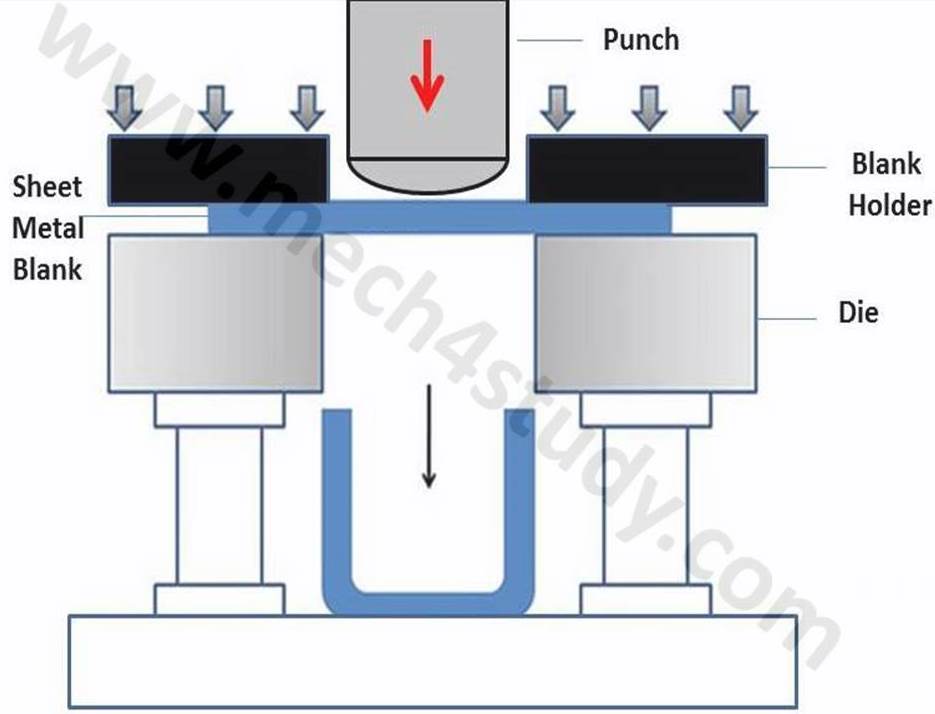

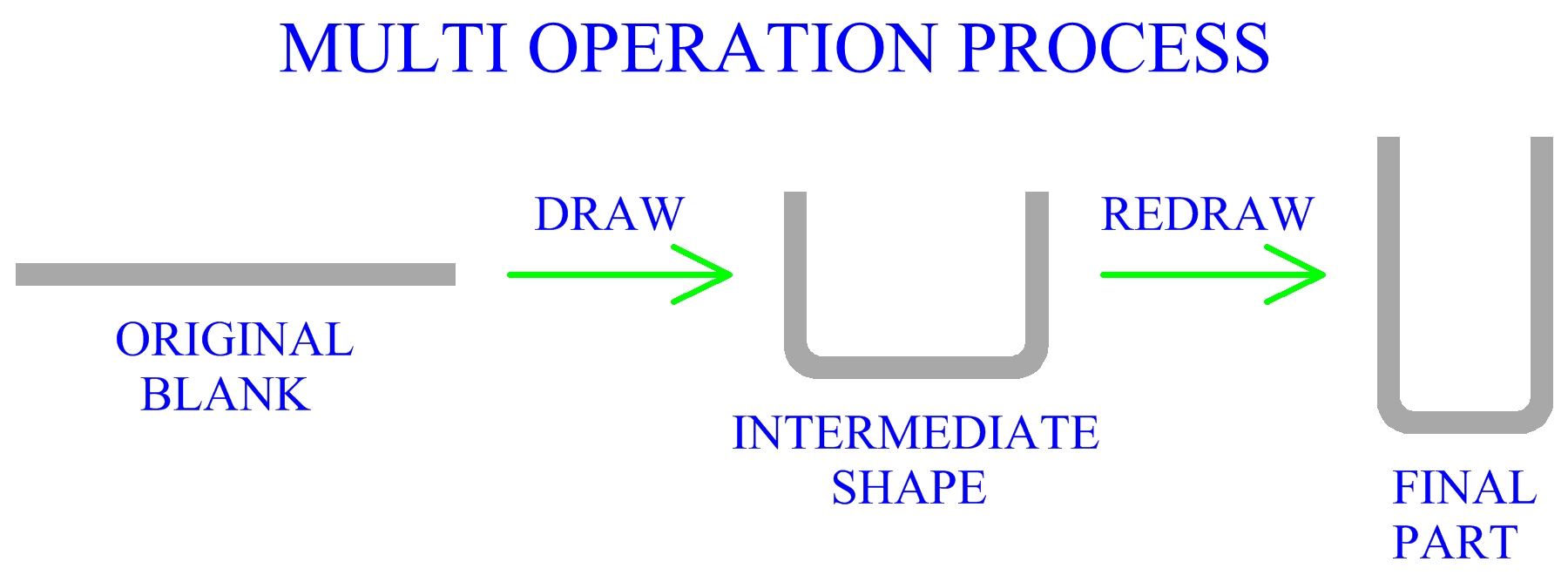

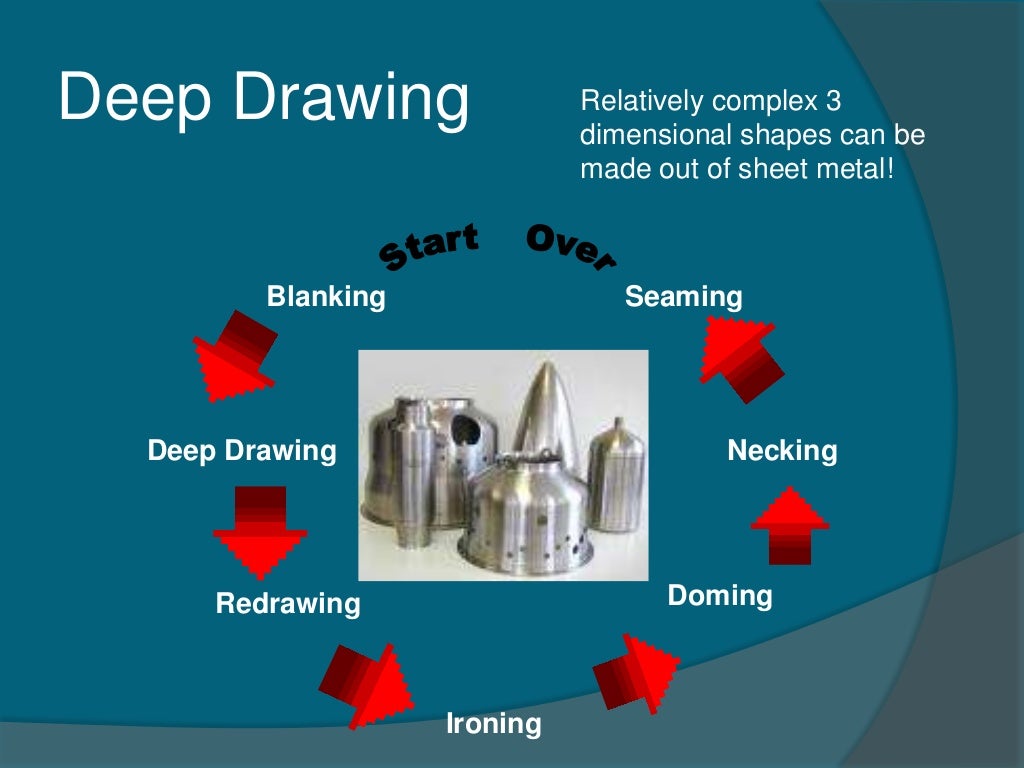

Process Of Deep Drawing - Web deep drawing specifically refers to the process of forming sheet metal into deep, hollow shapes by stretching the material into a die with a punch. Web the deep drawing process overview in its most basic form, deep drawing uses a punch to force a sheet metal blank into a die cavity to produce a tall, smooth,. Web deep drawing is a sheet metal forming process that involves using a punch and forming die to transform the metal into a desired shape. Web deep drawing is a sheet metal forming process in which a flat blank is constrained by a blank holder while the central portion of the sheet is pushed into a die opening with a. Web deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. Web deep drawing is one of the most widely used processes in sheet metal forming, in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a. Web process, diagram, advantages & applications. Web deep drawing is a process of converting metal sheet into cylindrical or box shaped structure with or without changing its length and thickness. Web the actual deep drawing process involves pushing a sheet of ductile metal (the blank) into a die by a punch, which forms it into the desired shape. For the pressing operations the process involves relatively shallow. Web process, diagram, advantages & applications. Web the actual deep drawing process involves pushing a sheet of ductile metal (the blank) into a die by a punch, which forms it into the desired shape. Web deep drawing is a sheet metal forming process that involves using a punch and forming die to transform the metal into a desired shape. For the pressing operations the process involves relatively shallow. Web the deformation is achieved by forcing the sheet metal into a formed female die using a male shaped punch. However, the process can also be used to. Web deep drawing is a process of converting metal sheet into cylindrical or box shaped structure with or without changing its length and thickness. Web the deep drawing process overview in its most basic form, deep drawing uses a punch to force a sheet metal blank into a die cavity to produce a tall, smooth,. Web deep drawing is one of the most widely used processes in sheet metal forming, in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a. Web deep drawing is a sheet metal forming process in which a flat blank is constrained by a blank holder while the central portion of the sheet is pushed into a die opening with a. It uses lines and points to give a sense of distance in views of the. Web deep drawing is a sheet metal forming process in which a flat blank is constrained by a blank holder while the central portion of the sheet is pushed into a die opening with a. Web deep drawing specifically refers to the process of forming sheet metal into deep, hollow shapes by stretching the material into a die with a punch. Web the deformation is achieved by forcing the sheet metal into a formed female die using a male shaped punch. Web the actual deep drawing process involves pushing a sheet of ductile metal (the blank) into a die by a punch, which forms it into the desired shape. Web deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. Web process, diagram, advantages & applications. Web the deep drawing process overview in its most basic form, deep drawing uses a punch to force a sheet metal blank into a die cavity to produce a tall, smooth,. Web deep drawn stamping refers to the process of forming sheet metal under compressive and tensile conditions to into a cavity, producing a closed bottom, round, or irregularly. For the pressing operations the process involves relatively shallow. Web deep drawing is a sheet metal forming process that involves using a punch and forming die to transform the metal into a desired shape. It uses lines and points to give a sense of distance in views of the. Web the deformation is achieved by forcing the sheet metal into a formed female die using a male shaped punch.. Web the deep drawing process overview in its most basic form, deep drawing uses a punch to force a sheet metal blank into a die cavity to produce a tall, smooth,. Web deep drawing is a process of converting metal sheet into cylindrical or box shaped structure with or without changing its length and thickness. Web the actual deep drawing. Web deep drawing is a sheet metal forming process that involves using a punch and forming die to transform the metal into a desired shape. Web the deformation is achieved by forcing the sheet metal into a formed female die using a male shaped punch. For the pressing operations the process involves relatively shallow. Web deep drawing is a process. It uses lines and points to give a sense of distance in views of the. Web the actual deep drawing process involves pushing a sheet of ductile metal (the blank) into a die by a punch, which forms it into the desired shape. For the pressing operations the process involves relatively shallow. Web deep drawing specifically refers to the process. Web deep drawing is a sheet metal forming process that involves using a punch and forming die to transform the metal into a desired shape. It uses lines and points to give a sense of distance in views of the. For the pressing operations the process involves relatively shallow. Web deep drawing is a metal forming process for creating seamless,. Web deep drawing is a process of converting metal sheet into cylindrical or box shaped structure with or without changing its length and thickness. Web the deformation is achieved by forcing the sheet metal into a formed female die using a male shaped punch. Web deep drawn stamping refers to the process of forming sheet metal under compressive and tensile. Web deep drawing is one of the most widely used processes in sheet metal forming, in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a. Web deep drawing is a process of converting metal sheet into cylindrical or box shaped structure with or without changing its length and thickness. Web deep. Web deep drawn stamping refers to the process of forming sheet metal under compressive and tensile conditions to into a cavity, producing a closed bottom, round, or irregularly. Web deep drawing specifically refers to the process of forming sheet metal into deep, hollow shapes by stretching the material into a die with a punch. However, the process can also be. Web deep drawn stamping refers to the process of forming sheet metal under compressive and tensile conditions to into a cavity, producing a closed bottom, round, or irregularly. Web deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. It uses lines and. For the pressing operations the process involves relatively shallow. Web deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. Web the deformation is achieved by forcing the sheet metal into a formed female die using a male shaped punch. Web process, diagram,. Web deep drawing is a sheet metal forming process that involves using a punch and forming die to transform the metal into a desired shape. Web the deformation is achieved by forcing the sheet metal into a formed female die using a male shaped punch. However, the process can also be used to. Web deep drawn stamping refers to the process of forming sheet metal under compressive and tensile conditions to into a cavity, producing a closed bottom, round, or irregularly. Web deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. Web the actual deep drawing process involves pushing a sheet of ductile metal (the blank) into a die by a punch, which forms it into the desired shape. Web deep drawing specifically refers to the process of forming sheet metal into deep, hollow shapes by stretching the material into a die with a punch. Web deep drawing is one of the most widely used processes in sheet metal forming, in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a. Web process, diagram, advantages & applications. For the pressing operations the process involves relatively shallow. Web deep drawing is a sheet metal forming process in which a flat blank is constrained by a blank holder while the central portion of the sheet is pushed into a die opening with a.DeepDrawn Process Our DeepDrawing Process

Deep drawing This resource is a diagram of the process use… Flickr

best deep drawing process, by chris YouTube

Introduction to Deep Drawing Process YouTube

Sheet Metal Deep Drawing Process

Schematic diagram of deep drawing process (a) two different punch

What is Deep Drawing? Process, Diagram, Advantages & Applications

What is Deep Drawing Process? mech4study

Deep Drawing Of Sheet Metal

Deep drawing

It Uses Lines And Points To Give A Sense Of Distance In Views Of The.

Web The Deep Drawing Process Overview In Its Most Basic Form, Deep Drawing Uses A Punch To Force A Sheet Metal Blank Into A Die Cavity To Produce A Tall, Smooth,.

Web Deep Drawing Is A Process Of Converting Metal Sheet Into Cylindrical Or Box Shaped Structure With Or Without Changing Its Length And Thickness.

Related Post: