Thread Callout On Drawing

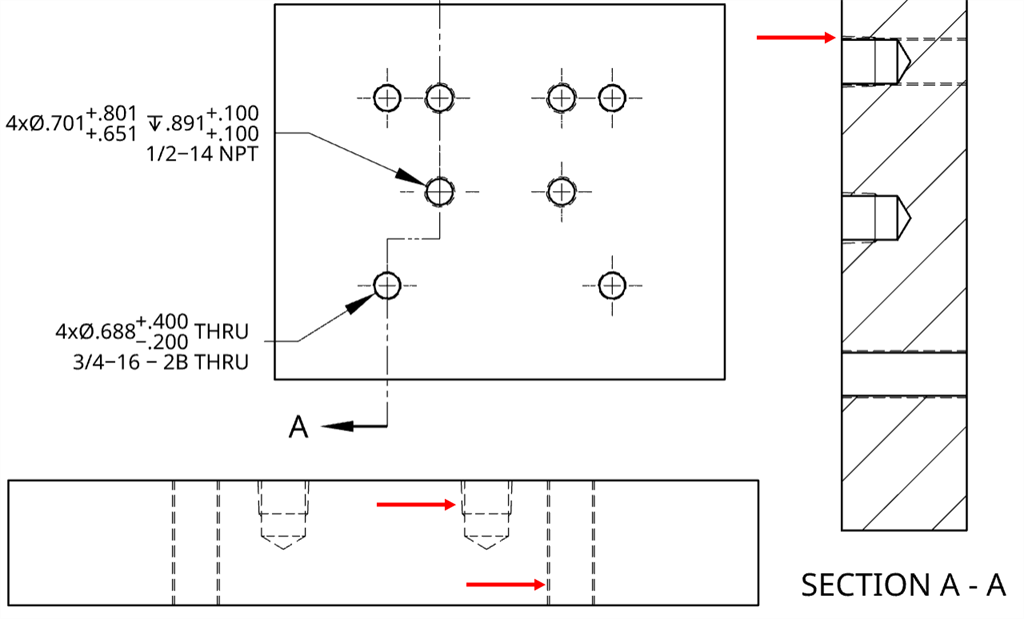

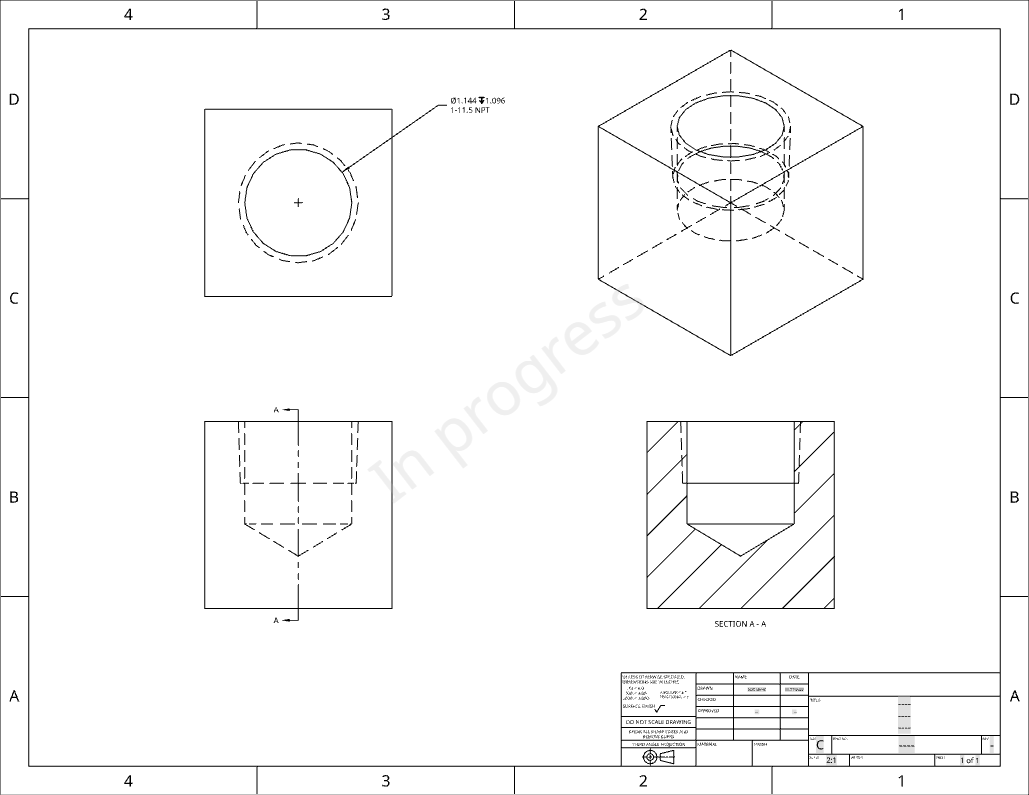

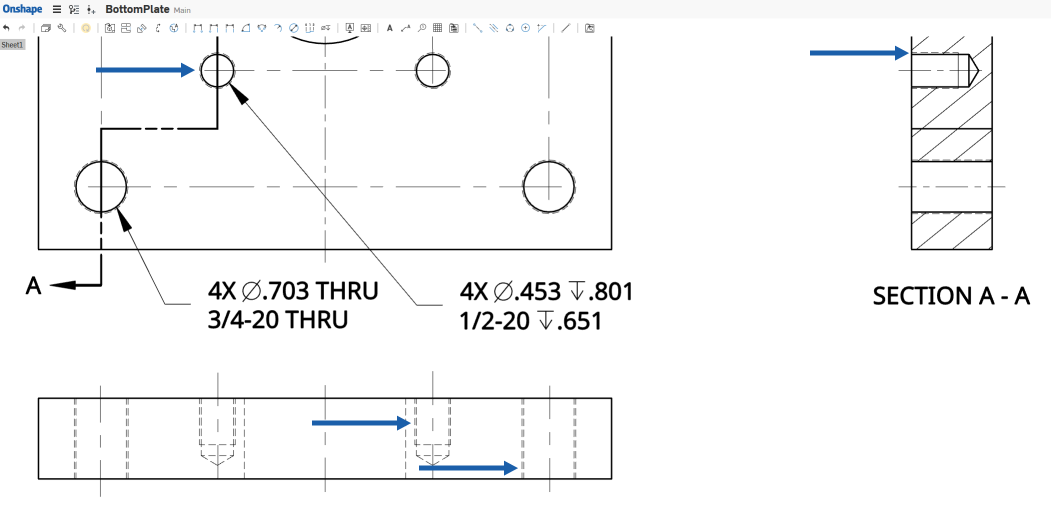

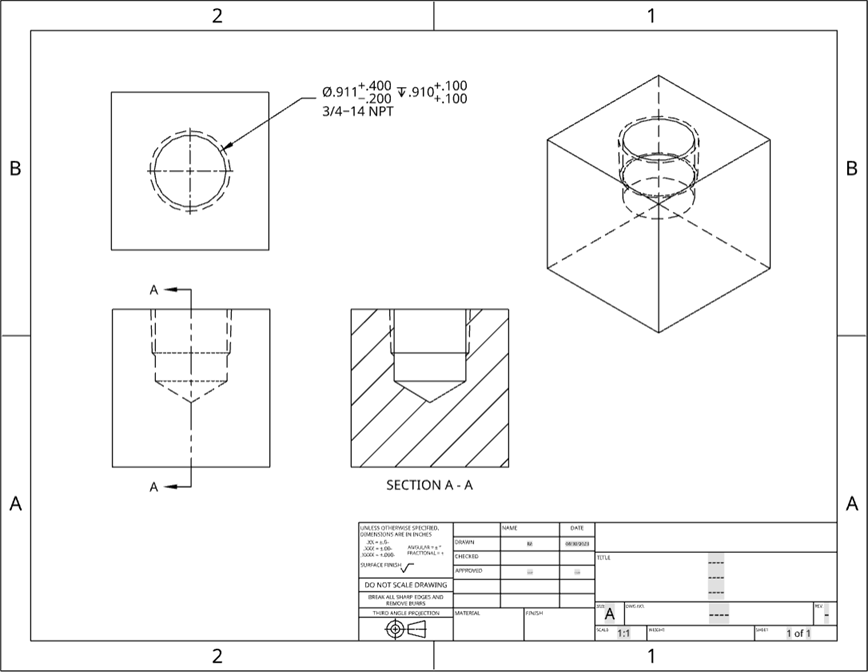

Thread Callout On Drawing - They are very particular about the predrill sizes in their specs (as i recall), and when i've worked with them, our manufacturing engineers had to play with the predrill sizes a bit to get a good combination of tapping speed and thread locking performance. Web thread classes are specified to designate the amount of tolerance allowance and installation fit desired. Web the thread callout is defined in the cosmetic thread feature of the source part or assembly. Web apply a hole callout to a hole or thread, automatically inserting the metadata of the hole or thread. Web threaded fasteners fastening is a method of connecting or joining two or more parts together, using processes or devices. In the above tap hole callout, we have given two callouts to understand it in both metric and inch systems. Web when you want to join two objects, but retain the ability to easily separate them, a great choice is to use a threaded connection. One of the most common methods used for fastening is mechanical fastening, a process that uses manufactured devices such as screws, pins, or rivets to. To understand the thread requirements on your drawing, you need to know common standard thread information. Steps creating a hole or thread callout: Web use the first number to figure out the diameter of the threads. Steps creating a hole or thread callout: Web the thread callout is defined in the cosmetic thread feature of the source part or assembly. Web threaded fasteners fastening is a method of connecting or joining two or more parts together, using processes or devices. In the above tap hole callout, we have given two callouts to understand it in both metric and inch systems. To understand the thread requirements on your drawing, you need to know common standard thread information. The first number shows you the major diameter or the diameter of the grooves on the screw shaft. Inch thread and metric thread callout on the engineering drawing. One of the most common methods used for fastening is mechanical fastening, a process that uses manufactured devices such as screws, pins, or rivets to. Web there are three methods of representing screw threads on a drawing. They are very particular about the predrill sizes in their specs (as i recall), and when i've worked with them, our manufacturing engineers had to play with the predrill sizes a bit to get a good combination of tapping speed and thread locking performance. Inch thread and metric thread callout on the engineering drawing. The first number shows you the major diameter or the diameter of the grooves on the screw shaft. Web thread classes are specified to designate the amount of tolerance allowance and installation fit desired. Web when you want to join two objects, but retain the ability to easily separate them, a great choice is to use a threaded connection. Steps creating a hole or thread callout: Web there are three methods of representing screw threads on a drawing. Web apply a hole callout to a hole or thread, automatically inserting the metadata of the hole or thread. One of the most common methods used for fastening is mechanical fastening, a process that uses manufactured devices such as screws, pins, or rivets to. Web threaded fasteners fastening is a method of connecting or joining two or more parts together, using processes or devices. Web thread classes are specified to designate the amount of tolerance allowance and installation fit desired. Web apply a hole callout to a hole or thread, automatically inserting the metadata of the hole or thread. In the above tap hole callout, we have given two callouts to understand it in both metric and inch systems. To understand the thread requirements. Steps creating a hole or thread callout: Web threaded fasteners fastening is a method of connecting or joining two or more parts together, using processes or devices. Web use the first number to figure out the diameter of the threads. Web when you want to join two objects, but retain the ability to easily separate them, a great choice is. The first number shows you the major diameter or the diameter of the grooves on the screw shaft. Web apply a hole callout to a hole or thread, automatically inserting the metadata of the hole or thread. Web ewh, the best example that i can think of is with specialized threads such as spiralok. Web threaded fasteners fastening is a. You use the smart dimension tool to add the callout in a side view or section view of the external thread. Web ewh, the best example that i can think of is with specialized threads such as spiralok. Web there are three methods of representing screw threads on a drawing. Web apply a hole callout to a hole or thread,. Web threaded fasteners fastening is a method of connecting or joining two or more parts together, using processes or devices. Web use the first number to figure out the diameter of the threads. In the above tap hole callout, we have given two callouts to understand it in both metric and inch systems. One of the most common methods used. Inch thread and metric thread callout on the engineering drawing. Web use the first number to figure out the diameter of the threads. To understand the thread requirements on your drawing, you need to know common standard thread information. One of the most common methods used for fastening is mechanical fastening, a process that uses manufactured devices such as screws,. Web the thread callout is defined in the cosmetic thread feature of the source part or assembly. The first number shows you the major diameter or the diameter of the grooves on the screw shaft. One of the most common methods used for fastening is mechanical fastening, a process that uses manufactured devices such as screws, pins, or rivets to.. Web use the first number to figure out the diameter of the threads. You use the smart dimension tool to add the callout in a side view or section view of the external thread. The first number shows you the major diameter or the diameter of the grooves on the screw shaft. Web apply a hole callout to a hole. Web apply a hole callout to a hole or thread, automatically inserting the metadata of the hole or thread. Web when you want to join two objects, but retain the ability to easily separate them, a great choice is to use a threaded connection. Web ewh, the best example that i can think of is with specialized threads such as. Web apply a hole callout to a hole or thread, automatically inserting the metadata of the hole or thread. You use the smart dimension tool to add the callout in a side view or section view of the external thread. Web use the first number to figure out the diameter of the threads. One of the most common methods used. Web thread classes are specified to designate the amount of tolerance allowance and installation fit desired. To understand the thread requirements on your drawing, you need to know common standard thread information. Inch thread and metric thread callout on the engineering drawing. Web when you want to join two objects, but retain the ability to easily separate them, a great choice is to use a threaded connection. They are very particular about the predrill sizes in their specs (as i recall), and when i've worked with them, our manufacturing engineers had to play with the predrill sizes a bit to get a good combination of tapping speed and thread locking performance. Web use the first number to figure out the diameter of the threads. Web ewh, the best example that i can think of is with specialized threads such as spiralok. In the above tap hole callout, we have given two callouts to understand it in both metric and inch systems. Steps creating a hole or thread callout: Web the thread callout is defined in the cosmetic thread feature of the source part or assembly. You use the smart dimension tool to add the callout in a side view or section view of the external thread. One of the most common methods used for fastening is mechanical fastening, a process that uses manufactured devices such as screws, pins, or rivets to.Hole/Thread Callout

Thread callout in drawing Siemens UG/NX EngTips

Hole/Thread Callout

Using Cosmetic Threads in SOLIDWORKS Parts and Drawings

Hole/Thread Callout

Hole/Thread Callout

3D Printing Threads (Cosmetic/Virtual Threads vs Real 3D Threads)

PPT Threads and Fasteners PowerPoint Presentation, free download ID

Threaded Hole Callout Standard A Pictures Of Hole 2018

How to prepare a technical drawing for CNC machining Hubs

The First Number Shows You The Major Diameter Or The Diameter Of The Grooves On The Screw Shaft.

Web There Are Three Methods Of Representing Screw Threads On A Drawing.

Web Threaded Fasteners Fastening Is A Method Of Connecting Or Joining Two Or More Parts Together, Using Processes Or Devices.

Web Apply A Hole Callout To A Hole Or Thread, Automatically Inserting The Metadata Of The Hole Or Thread.

Related Post: